Carbon Nanotubes

High-Density, Ultralong Carbon Nanotubes (UL CNTs)

Carbon nanotubes have gained significant interest in industries ranging from aerospace and defense to nanoelectronics due to their desirable mechanical and electrical properties. The trouble with CNTs to date has been the difficulty of fabricating a significant mass of nanotubes economically. Increasing the density of nanotube forests in a given fabrication process is helpful, but the need to combine many shorter tubes (often < 10 µm) into composite ‘yarns’ results in degraded mechanical, thermal, or electrical integrity. The ability to grow continuous ultralong nanotubes (> 100 µm) is thus highly desired in nearly all applications to which CNTs have been applied. Some applications won’t realistically be able to take advantage of their various extraordinary properties until the mass production of ultralong tubes has been achieved.

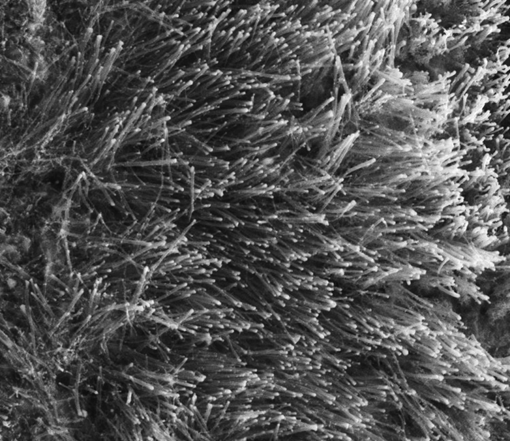

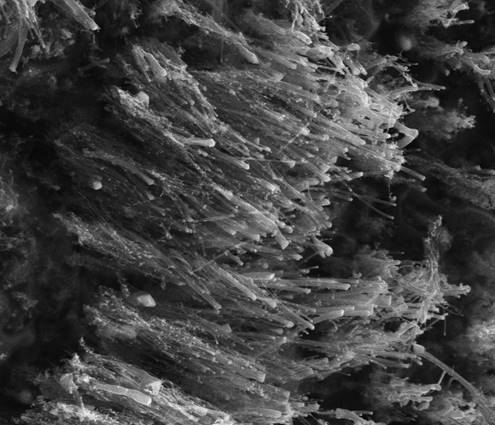

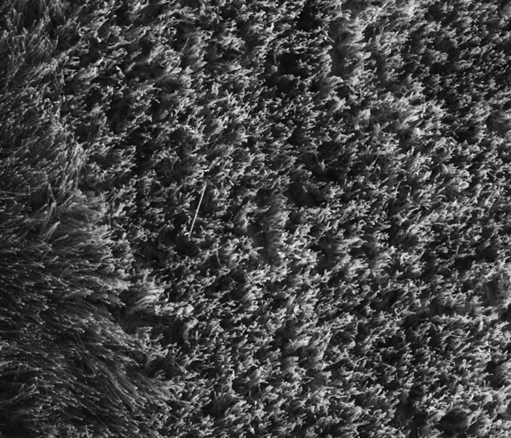

At Nanomatronix, we’re developing a high-temperature CNT synthesis system based on a modified plasma-enhanced chemical vapor deposition (PECVD) chamber. We’ve achieved the ability to grow dense CNT forests directly on bulk metal catalyst substrates, an advancement that speeds CNT fabrication procedures significantly, as no micro/nanoscale metal deposition steps are required to prepare our substrates. We’re working to refine our process to produce ultralong CNTs with high density and to improve our control over nanotube type (single or multi-walled), chirality, and uniformity. SEM images are displayed below, showing examples of CNT forests grown directly on bulk catalyst substrates.

Contact us

We’re here to answer any questions you might have. We look forward to hearing from you.

Interested in working with us? Tell us about your project!